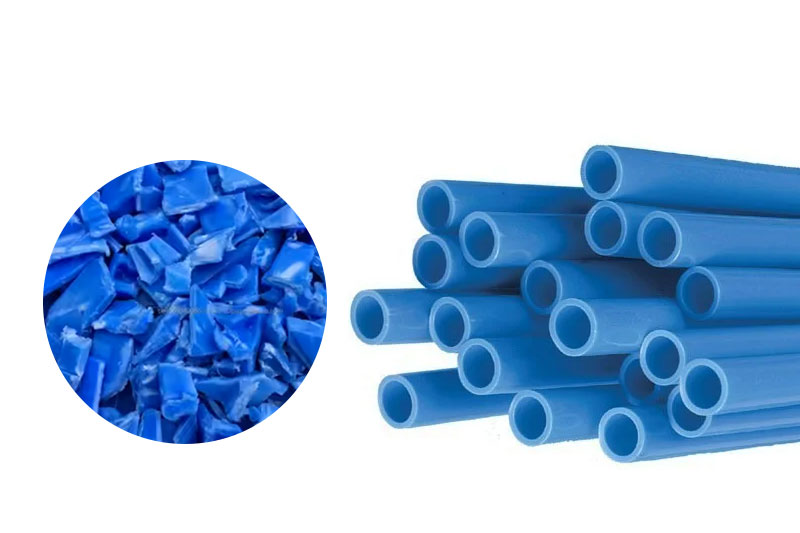

PP HDPE Hard Plastic Recycling Washing Line

This line efficiently removes dirt, labels, oil, and other contaminants through a complete process of shredding, crushing, washing, separation, and drying — transforming waste plastic into clean, reusable flakes.

Fill out my online form.

1

Feeding & Conveying

Waste PP/HDPE materials are loaded and transported to the shredder automatically.

2

Shredding

A Double Shaft Shredder cuts bulky plastics into smaller, manageable pieces.

3

Crushing

A Crusher grinds shredded pieces into uniform flakes suitable for washing.

4

Friction Washing

High-speed friction cleaning removes surface dirt, oil, and labels.

5

Hot Washing

Heated water and detergent clean off stubborn oil and glue residues.

6

Floating Washing Tank

Separates floating PP/HDPE flakes from heavier impurities by density.

7

Drying System

Removes moisture from flakes using centrifugal or horizontal dryers.

8

Label Separator

Air separation eliminates light label or film residues for higher purity.

9

Storage & Collection

Clean, dry flakes are collected in silos or bags for reuse or pelletizing.

10

Final Output

Produces high-quality recycled PP/HDPE flakes ready for pelletizing or molding.

Technical Parameters

| Model | Capacity (kg/hr) | Installed Power (kW) | Power Consumption (kW/hr) | Water Consumption (m³/hr) |

|---|---|---|---|---|

| KL-300 | 300 | 100 | 70 | 4–5 |

| KL-500 | 500 | 120 | 85 | 6–8 |

| KL-800 | 800 | 180 | 130 | 8–9 |

| KL-1000 | 1000 | 220 | 160 | 9–10 |

| KL-2000 | 2000 | 350 | 245 | 13–15 |

Machine Details

Belt Conveyor

Feeds rigid plastic waste such as HDPE bottles, PP buckets, or drums evenly into the shredder or crusher.

Ensures stable and continuous operation throughout the recycling line.

Crusher

Further crushes pre-shredded materials into uniform flakes.

Equipped with high-strength SKD11 blades and water-assisted cutting to prevent heat buildup and deformation.

Friction Washer

High-speed washer that removes sand, dirt, labels, and oil residues through mechanical scrubbing and water spray.

Improves flake cleanliness before sink-float separation.

Washing Tank

Separates materials by density — clean HDPE/PP flakes float while heavy contaminants sink.

Ensures the removal of paper, metal, and other impurities.

Vertical Dewater

Centrifugal system that removes surface water from washed flakes.

Reduces moisture to below 5% and prevents material loss during drying.

Silo

Centrifugal system that removes surface water from washed flakes.

Reduces moisture to below 5% and prevents material loss during drying.

Drying System

The Drying System is designed to remove residual moisture from washed plastic flakes such as HDPE, PP, or LDPE films after dewatering.

Screw Loader

The squeezer machine combines mechanical squeezing and heat friction to further dewater and densify the washed film flakes.

Electric Cabinet

A.DELIXI Main Electrical

B.SIEMENS Contactor

C.Emergency stop switch on the front panel

D.Each part of the state of the equipment are working on a display panel meter

E.Equipped with overload protection device

B.SIEMENS Contactor

C.Emergency stop switch on the front panel

D.Each part of the state of the equipment are working on a display panel meter

E.Equipped with overload protection device

Final Product & Applications